Compost Tea System100™

The System100, our most popular model, is ideal for operations of 10 to 50 acres. This durable System meets the needs of daily compost tea users including mid-size farms, landscape contractors, garden centers, and compost facilities. The System100’s patented design and industrial grade components ensures efficient and reliable Compost Tea production.

- Patented Compost Tea System design

- Fine Bubble Air Diffusion technology

- Industrial grade components

- Highest quality aeration system available

- Four durable and easy-to-handle compost filter baskets

Specifications

| Tank capacity | 100 gallons/400 liters |

| Aeration | Fine Bubble Diffusion |

| Air delivery | Siemens® regenerative air blower |

| Electrical | 110V/220V |

| Tank/Stand | UV stabilized polyethylene |

| Valves/fittings | Banjo® glass-filled polypropylene |

| Fasteners | 18-8 Stainless steel |

| Weight | 250 pounds/114 kilos |

| Dimensions | 64 x 54 x 56 inches 163 x 137 x 140 centimeters |

| Brew time | 24 hours |

Growing Solutions patented

Fine Bubble Diffusion technology

All Growing Solutions Compost Tea Systems use our Fine Bubble Diffusion dynamic aeration process. Each Fine Bubble Diffusion aeration disc has 4,000 engineered perforations (1mm in size) that provide consistent air bubble size and velocity. The Compost Tea solution is thoroughly mixed by the Fine Bubble Diffusion aeration process inside the tank, eliminating the need for external agitation. This dynamic aeration process ensures maximum oxygen transfer efficiency, creating an optimum environment for reproduction of beneficial aerobic microorganisms. Each disc’s perforations self seal when the Compost Tea System is off, preventing back flow of Compost Tea into the air manifold.

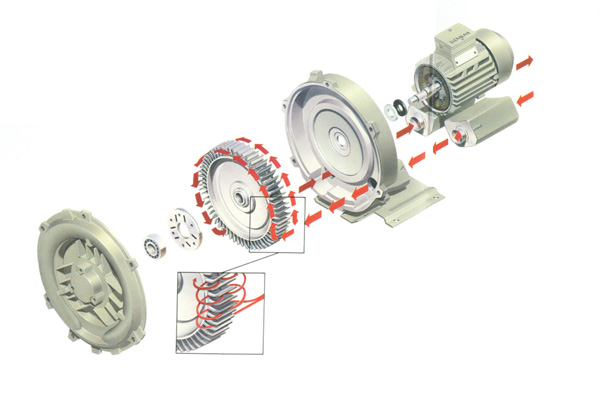

Siemens® regenerative air blower

We have selected the Siemens regenerative air blower for its long term performance in the field, high volume air output and reliability. An essential component to our Compost Tea System technology, this blower’s precision German engineering puts it at the top of its class. The precision impeller design provides unmatched air delivery volume efficiency.

Unmatched air delivery volume efficiency

This schematic offers an exploded view of the blower’s components, including the precision impeller design that provides unmatched air delivery volume efficiency.

Fine Bubble Diffusion aeration discs

Fine Bubble Technology aeration discs are found in all of our Compost Tea Systems. This aeration technology had been in use for more than 40 years in many applications throughout the world. The intelligent design of these discs help to realize highly efficient transfer of oxygen in the Compost Tea solution. The aeration discs are engineered with 4,000 1mm perforations with a one-way release air valve, a self-sealing design that prevents back-flow of any liquid when the disc is not inflated. The discs provide a high volume of aeration that creates a thorough homogeneity throughout the tank, eliminating the need for external mechanical mixing of the compost tea solution.

Fine Bubble Diffusion aeration system

The System100 has four Fine Bubble Diffusion aeration discs in the base of the tank. Strategic placement of the discs directly underneath the compost filter baskets ensures thorough mixing and oxygen availability at the immediate area of extraction.

Compost filter baskets airstone manifold

The System100 incorporates four sintered ceramic airstones placed in each of the four compost filter baskets. These industrial crafted airstones release a consistent pattern of air bubbles under low pressure in the center of the compost filter baskets, creating a buoyancy-effect that prevents compost compaction during the 24 hour brewing process. This additional air flow allows for a greater extraction of microbiology, nutrients and organic compounds. The airstones also provide oxygen inside the compost filter baskets, ensuring that proper oxygen levels are maintained.

Stainless steel filter baskets

The System100’s industrial stainless steel and ABS compost filter basket is manufactured under rigorous quality standards. Incorporating precision stainless steel water jet and CNC laser cutting technology, this filter basket is extremely durable, designed for extended field-longevity and is the top of its class in compost extraction efficiency.

Custom engineered compost filter basket tray

The System100’s custom engineered compost filter basket tray houses four compost filter baskets placed in fixed locations directly over the Fine Bubble Diffusion aeration discs in the bottom of the tank ensuring a high volume of air is surrounding the filtration area. This ABS tray is manufactured by an industrial vacuum-forming process to aerospace standards for precision, durability and longevity, and is completely recyclable.

Adding Compost Tea Catalyst

OMRI Listed for quality assurance and organic compliance, Growing Solutions Compost Tea Catalyst is a unique blend of ingredients formulated to stimulate diverse microbial growth during aerated Compost Tea production. Compost Tea Catalyst is a balanced nutrient source that significantly increases the biodiversity and growth of microorganisms found in compost. Available in five convenient sizes depending on your production needs.